TOP>

Products>

Refractory>

Refractories for cast iron and cast steel >

Monolithic refractories for cupola(Castable, Ramming material)

We provide suitable products to satisfy various cupola

operating conditions.

Monolithic refractories for cupola

"Castable, Ramming material"

- Ultimate monolithic products for cast iron.

- Line-up products to meet various operating conditions.

- To meet various lining design.

- To meet various needs such as metal resistance, slag

resistance, insulation resistance.

■Characteristics |

| Application |

Product

Name |

Chemical

composition(%) |

Installation

quantity

(/㎥) |

Installation

method |

Kneading water

quantity

(%) |

Note |

| Al2O3 |

SiC |

F.C. |

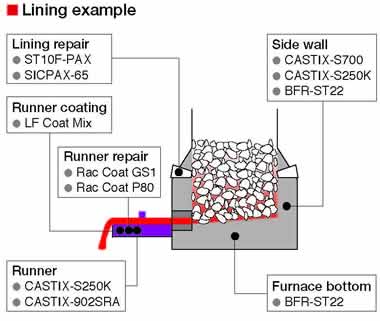

Cupola lining

(Furnace bottom ~

Inner wall) |

BFR-ST22 |

65 |

25 |

5 |

2,700 |

R |

- |

High corrosion

restance |

Cupola lining

(Inner wall) |

CASTIX-S700 |

23 |

69 |

3 |

2,700 |

C |

5.5 to 6.5 |

High corrosion

restance |

Cupola lining

(Inner wall ~

Trough) |

CASTIX-S250K |

65 |

26 |

3 |

2,900 |

C |

5.5 to 6.5 |

High corrosion

restance |

Cupola lining

(lining ~ Trough) |

ST10F-PAX |

55 |

28 |

4 |

2,750 |

P |

- |

High corrosion

restance |

Cupola lining

(lining ~ Trough) |

SICPAX-65 |

28 |

65 |

3 |

2,700 |

P |

- |

Carbon base

soft type |

Cupola

Trough |

CASTIX-902SRA |

85 |

9 |

- |

3,200 |

C |

4.5 to 5.5 |

Non-carbon

base soft type |

| Cupola trough reparing |

Rac Coat

GS1 |

68 |

15 |

5 |

2,750 |

P |

- |

Carbon base

soft type |

| Cupola trough reparing |

Rac Coat

P80 |

84 |

- |

- |

2,750 |

P |

- |

Non-carbon

base soft type |

| Cupola trough coating |

LF Coat Mix |

60 |

- |

8 |

- |

G |

50 to 70 |

Easy slag off,

protect

refractories |

Cupola trough coating |

SUPER COAT

P95SAL |

- |

- |

- |

3,000 |

G |

13 to 25 |

Easy slag off,

protect

refractories |

Installation method R:Ramming, C:Casting,

P:Patching, G:Gunning (Coating)) |

※These figures are typical values

but not guaranteed values. |

|

|

■Air setting high alumina base mortar

|

Maximum

temperature

(℃) |

1650 |

Chemical

compositions

(%) |

Al2O3 |

51 |

| SiO2 |

40 |

| Maximum particle size(mm) |

0.5 |

Installation quantity(kg)

(Nomal brick 1000pcs.) |

210 to 250 |